|

Elastomeric pads

are made of polychloroprene(neoprene) or polyisoprene(natural rubber). Elastomeric pads with properly design, manufacture and installation can transfer loads uniformly, accommodate thermal movements, and isolate vibration, impact & noise from buildings or structures.

Characteristics:

|

|

|

Lightweights,

simple to install, space-saving, long life cycle and economic |

|

No brittle in cold weather

|

|

|

Maintenance free |

|

Low compression set, creep resistant

|

|

|

Oil and chemical resistant |

|

Excellent shock and vibration damping

|

|

|

Burned resistance |

|

Accommodate thermal movements

|

|

|

TYPES:

|

|

1. Plain Pad

|

|

|

|

|

Elastomeric pad for pot bearing

|

Anti-seismic pad, Pad for rod

|

The shape made to satisfy

customers' requirements

|

|

|

|

|

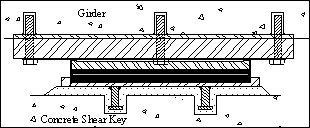

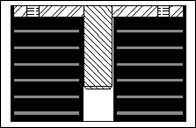

2.

Laminated Elastomeric Bearing

|

|

|

|

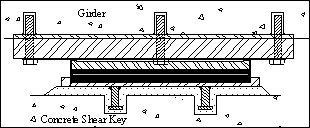

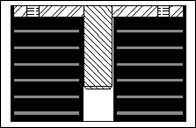

| 3. Sliding Bearing |

|

|

|

| 4. Other Application |

|

|

|

The laminated elastomeric bearings can be made various types to satisfy customers’ requirements. For example, we designed and manufactured for THSR C250&C270 with anchor bolts connecting devices and with holes for bolts or steel rods.

|

|

|

|

|

|

|

THSR C250&C270 |

THSR C270 |

|

|

|

|

|

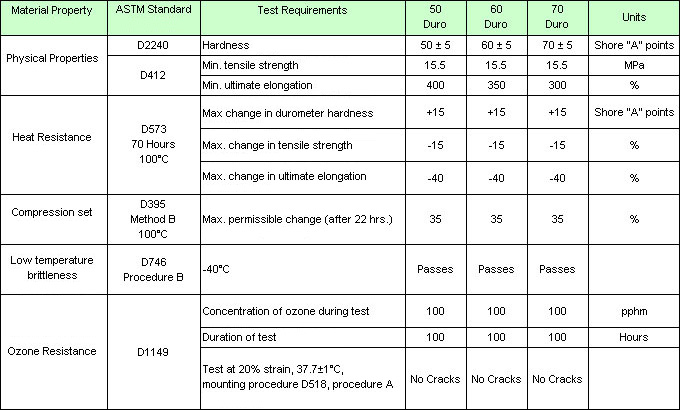

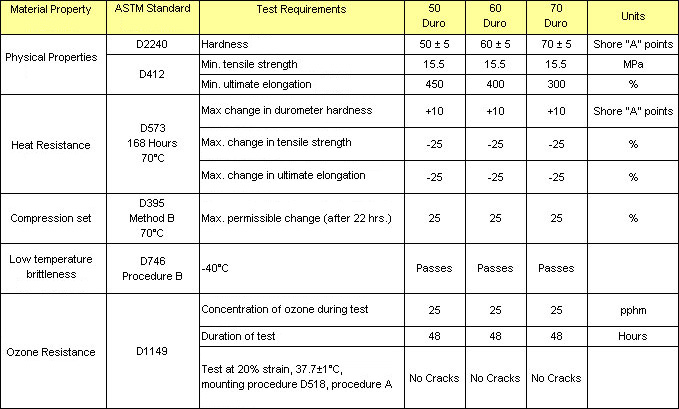

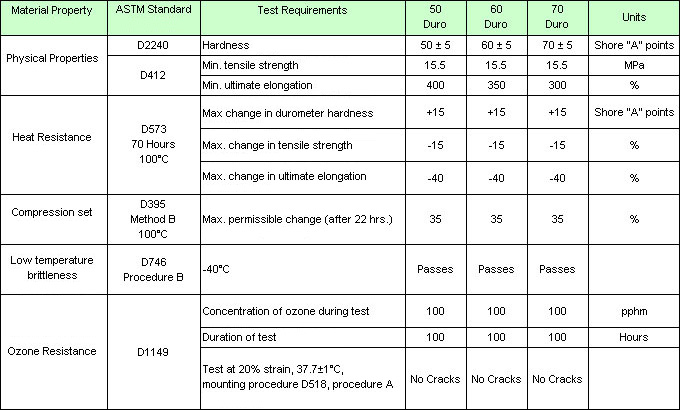

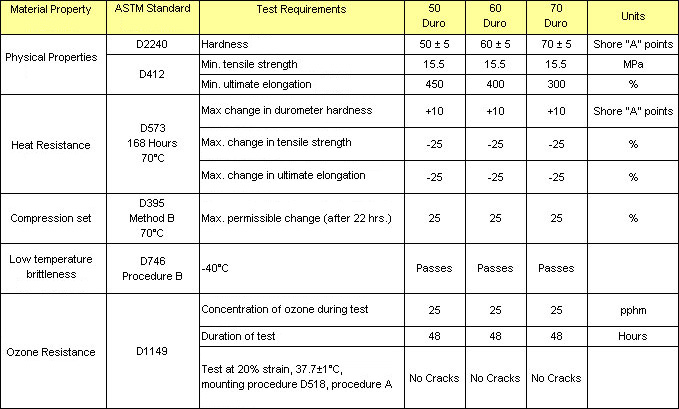

LIST OF ELASTOMER PROPERTIES: Source-AASHTO M251-97 |

|

Properties of Polychloroprene (Neoprene) |

|

|

|

|

|

Properties of Polyisoprene (Natural Rubber) |

|

|

|

|

|