|

|

| Elastomeric Pad |

| Pot Bearing |

| Cast Iron Bearing |

| Seismically Isolated Bearing |

| Bridge Expansion Joint |

| Shear Resisting Device |

| Other Products |

|

Pot bearing was first appeared in Europe in 1959. It is the most popular metal type bearing for bridges and buildings. In 1996, we took the lead in researching and designing pot bearings in Taiwan. Our pot bearings with well quality have been produced more than 20000 sets and earned highly appreciation. Characteristics: |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Types: | ||||||||||||||||||||||||

|

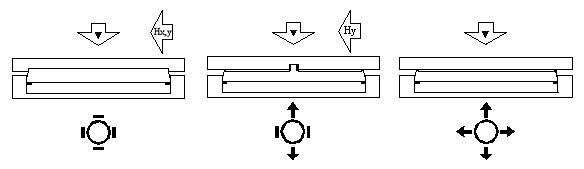

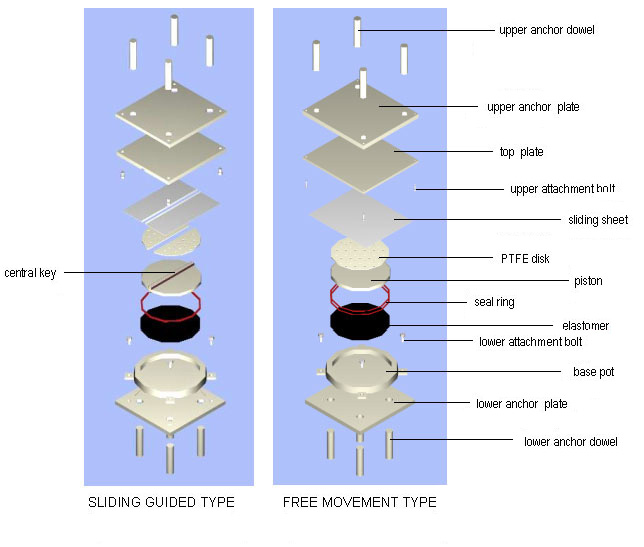

Pot bearing are available in three

type: fixed, sliding guided and free movement. .Fixed type: accommodate vertical load and provides restraint in all horizontal directions (hinge). .Sliding guided type: accommodate vertical load and allow one horizontal direction sliding and restraint the other horizontal directions (roller). .Free movement type: only accommodate vertical load and all the horizontal direction are free to move (roller). |

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

LF type LG type LM type |

||||||||||||||||||||||||

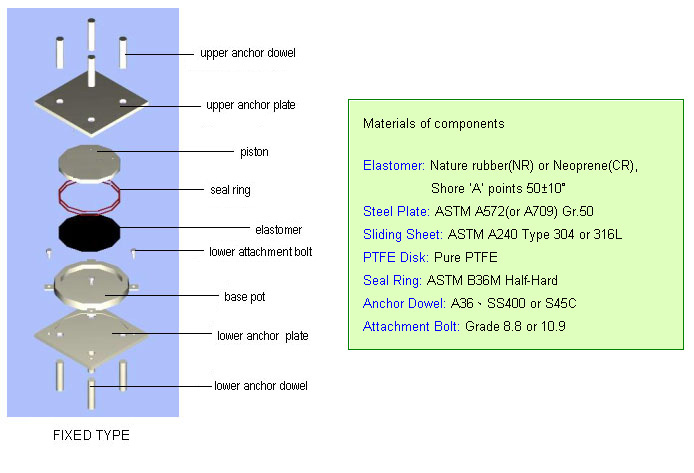

| Composition description: | ||||||||||||||||||||||||

|

This following figure is for the superstructure and substructure of pot bearing is concrete. If the superstructure or substructure is steel, the installation method shall be bolt or welding connecting. |

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Features: | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

Design code: AASHTO, prEN 1337, BS 5400 or client’s specification. Design condition: |

||||||||||||||||||||||||

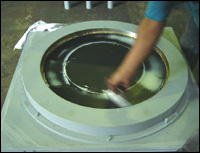

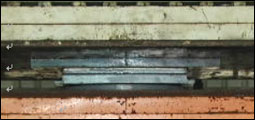

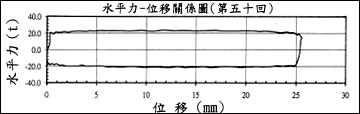

| Test of Completed Pot Bearing: In Taiwan, the requirement of pot bearing is in accordance with AASHTO 1996. The fixed types shall perform proof load test. The sliding types shall perform proof load test and sliding coefficient of friction test. |

||||||||||||||||||||||||

|

|

||||||||||